Install a Sight Glass fitting

Installing a Sight glass fitting

MALE NPT (PIPE) THREADS REQUIRE WHITE OR YELLOW PTFE (TEFLON) PLUMBERS TAPE BEFORE ASSEMBLY. YOU WILL GALL (BOND) THE THREADS WITHOUT IT.

PROTECT YOUR Valves, bulkheads, tubing and sight gauge from direct flame exhaust. Sight gauge tubing will soften / melt if flame wash heats it past 250 F.

Liquid will boil if you do not shield the fittings.

Silicone o-rings and (PTFE) teflon valve seals will melt if you dry fire your keg or kettle. Silicone tubing will melt if it touches hot parts. Thermometers have glass faces but the plastic seal on the face will melt if you allow it be in the flame exhaust.

To remove debris, a short soak in powdered brewery wash or oxyclean and a gentle scrub with a nylon tube brush.

DO NOT SOAK FOR LONGER THAN 30 minutes to prevent cracking of your tube

A HEAT SHIELD (a piece of flat metal under the edge of your kettle) should be used to keep the flames off the sight gauge, valves and thermometers.

Tools needed:

1/8” Starter bit

Step bit or hole saw. The best hole size is just a bit larger than 13/16”. 7/8” will work but will be loose.

Metal cutting lubricant

center punch

emery cloth or fine grit sand paper

Cordless drill to fit the step bit. Use a helper!

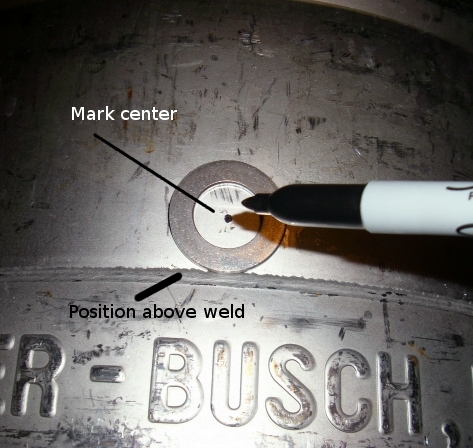

Position locknut just above the curve of pot, mark the center with a permanent marker and use your center punch so bit won't wander.

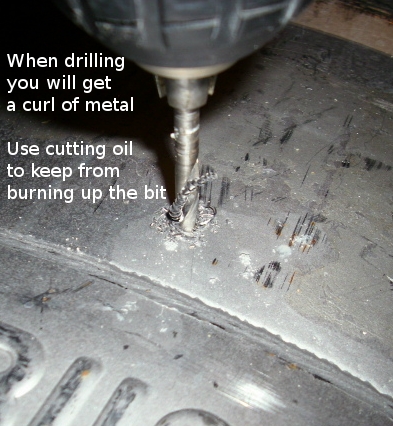

Drill slowly with your starter bit keeping the bit lubricated with cutting oil or soapy water

Switch to your step bit and drill slowly keeping the bit lubricated the whole time

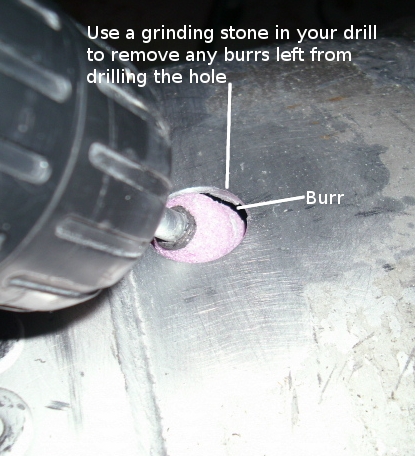

Clean hole up with a file or a grinding bit

ALUMINUM DRILLING: This metal cuts much easier than SS. Moderate speed and low pressure is best. It tends to grab the bit and can warp the metal quickly if you lose control of the vessel when drilling. USE A HELPER.

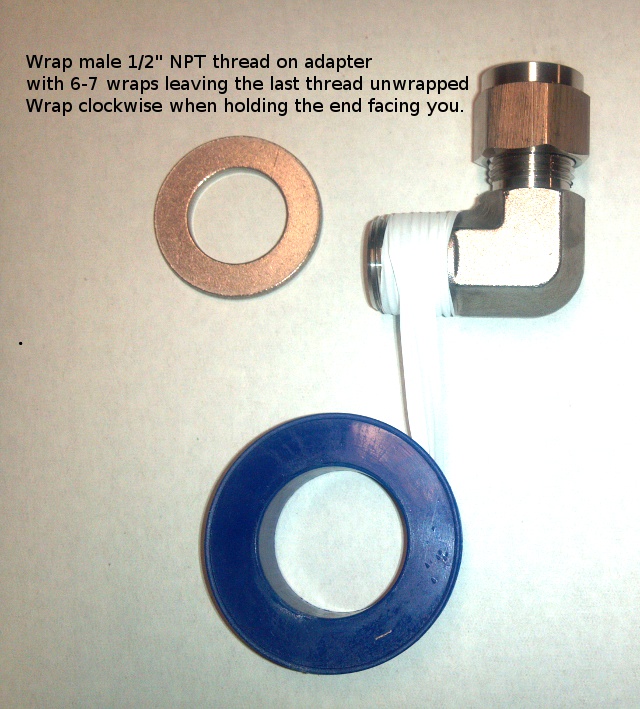

Wrap 5 or 6 wraps of white teflon tape on each side nipple threads. Yellow gas teflon tape is thicker 3 to 4 wraps is enough. Wrap in direction of the thread.

KEG WELDLESS BULKHEAD KIT INSTRUCTIONS:

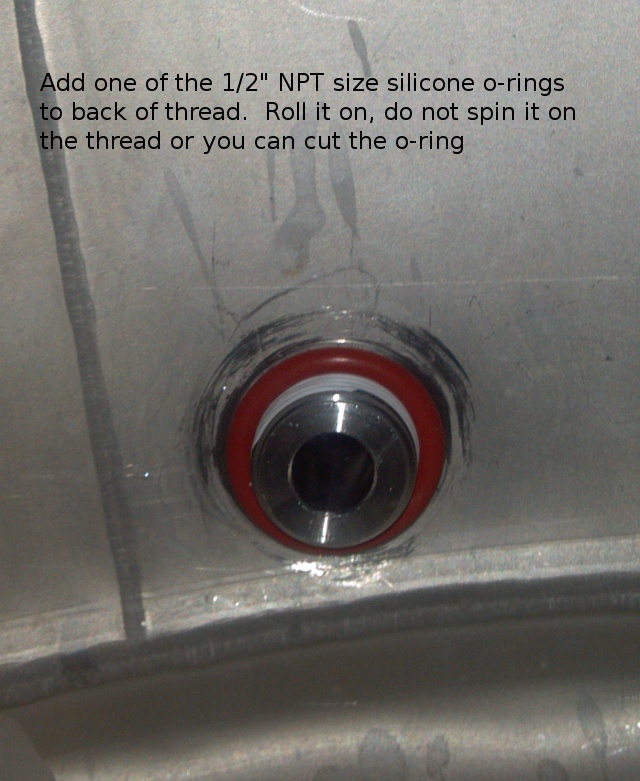

Insert through the hole of the keg

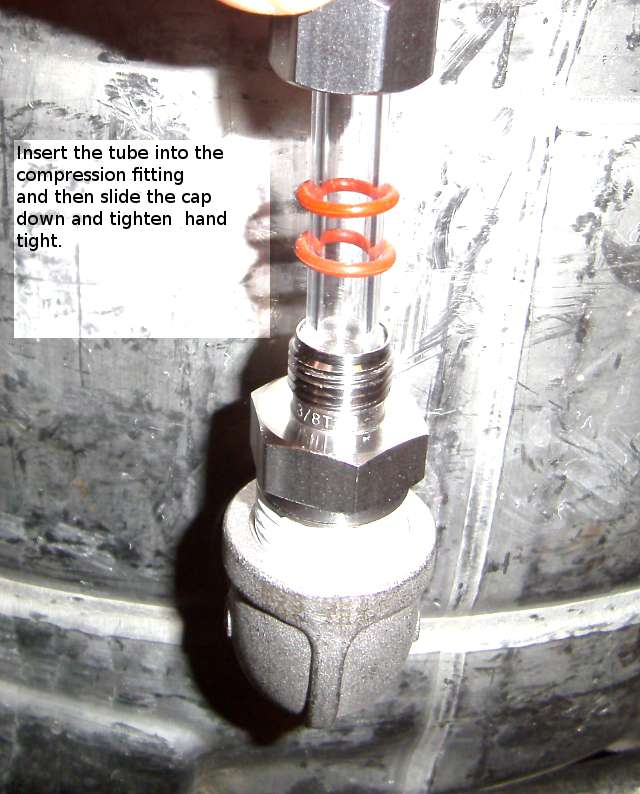

Add the compression cap and small o-ring.

You will roll the o-ring into the cap by pulling down on the compression cap.

Tighten the cap.

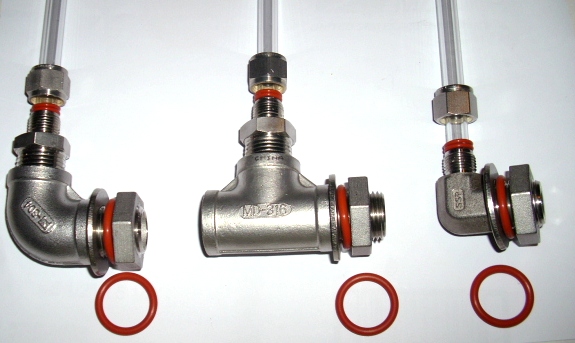

Cooler / keg style sight gauge.

Add an oring, and thread locknut on one end. Place through wall of keg from inside. 2nd oring is a spare.

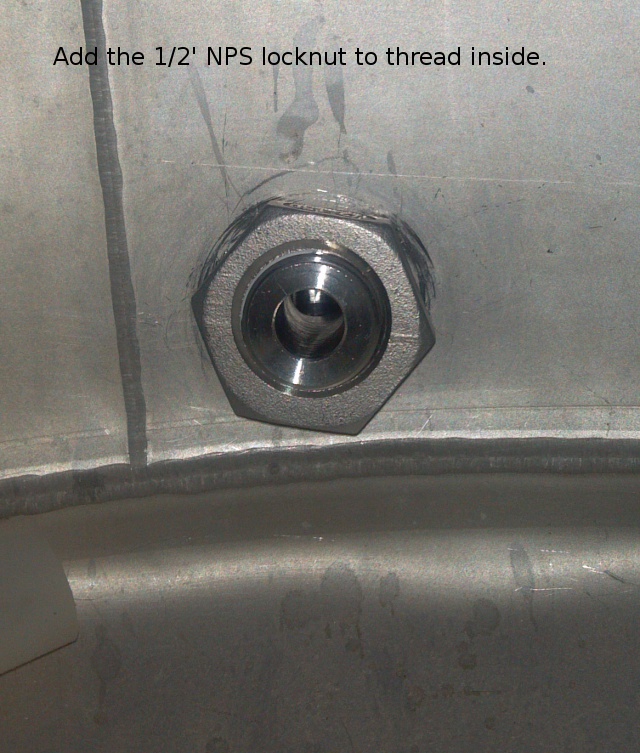

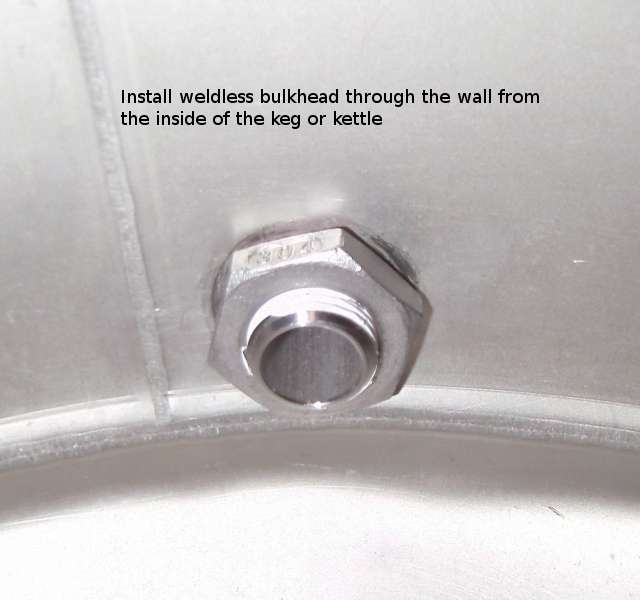

Install the fitting set through the wall from the inside

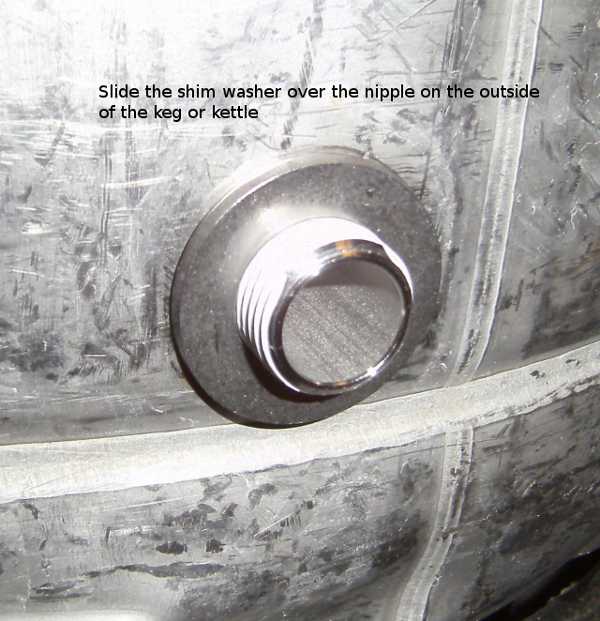

Apply the washer over the nipple on the outside

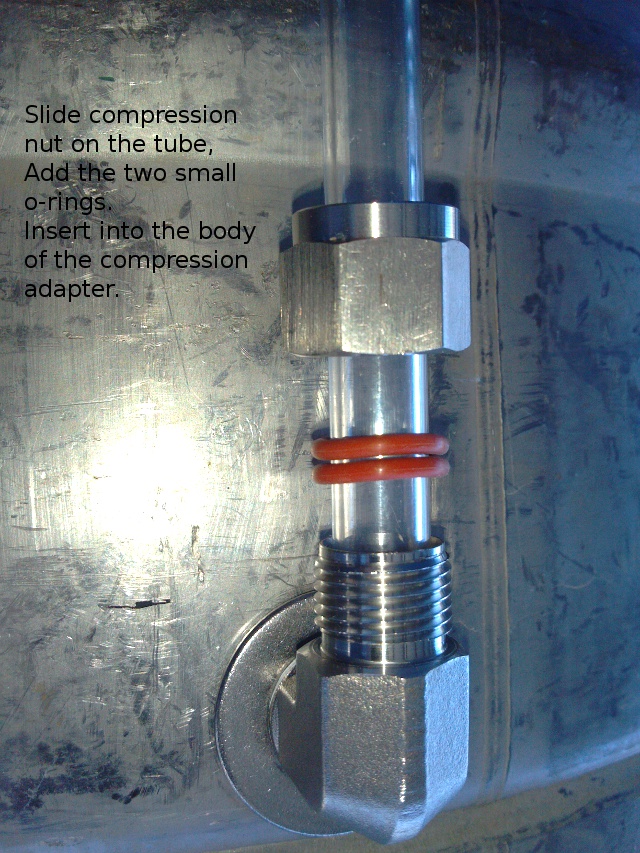

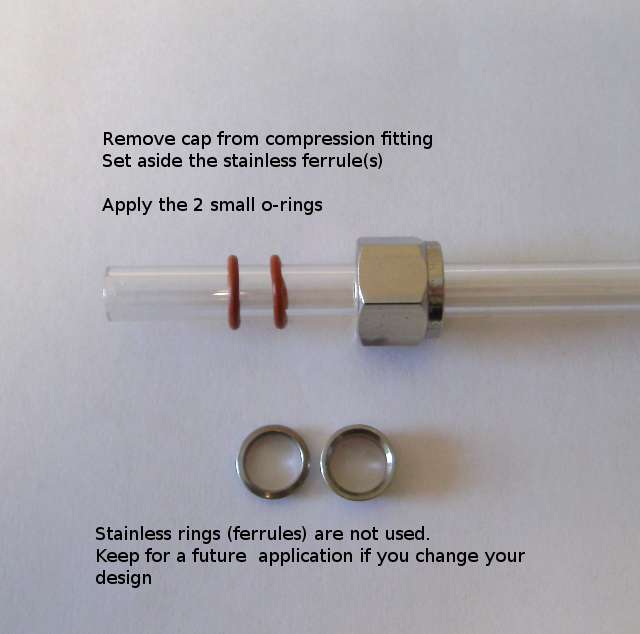

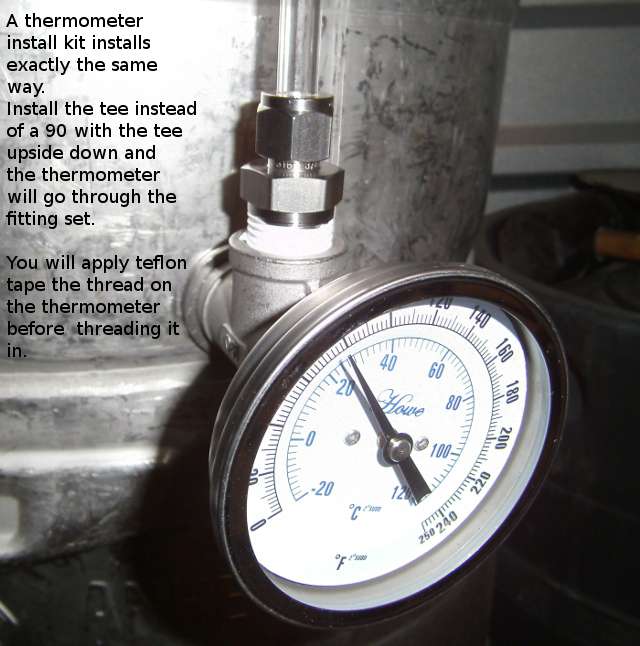

Wrap several wraps of teflon tape on the large NPT thread on the compression adapter fitting and thread into the 90 or Tee. Remove nut from the compression fitting and slide it on the tube.

Install into the Tee or 90

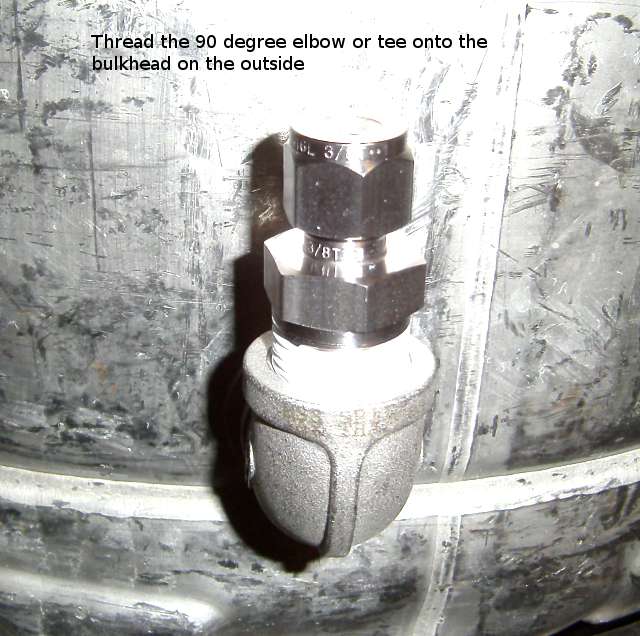

Thread on the 90 degree elbow or Tee. Grip the locknut with pliers and use pliers on the elbow (or Tee) to further tighten down the fitting set. Do not overtighten. You just want it snug against the metal. If you have to tighten it all the way down just make sure the o-ring does not pop out.

Add the two small o-rings and insert tube end in the compression side of the adapter fitting and hand tighten the nut. The orings will form the seal. Do not put teflon tape on the small thread on the compression side. Close any valves on the pot and fill enough water to submerge the coupler/locknut inside and watch outside for leaks.

A thermometer sight gauge fitting is install the same. Just replace the Tee for the 90 and then install your thermoter through the TEE fitting

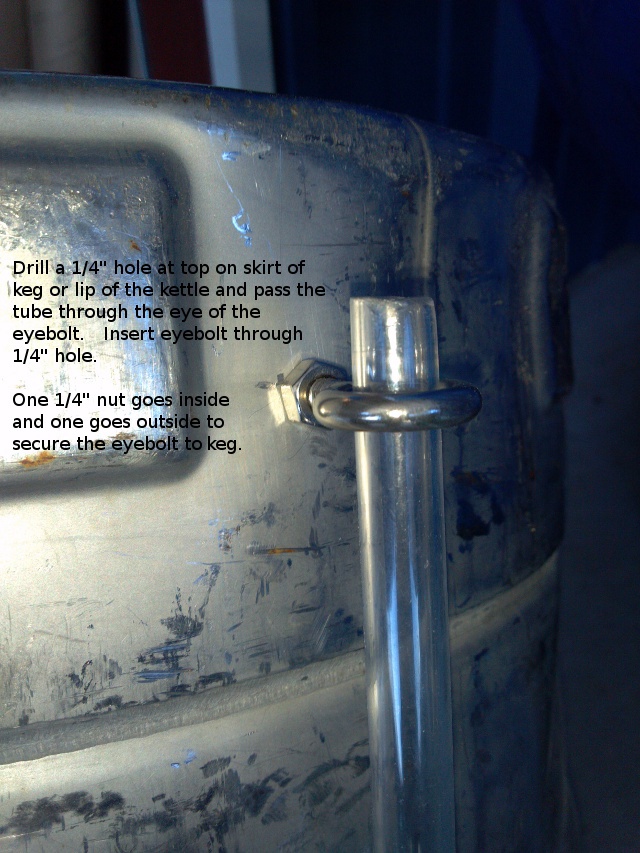

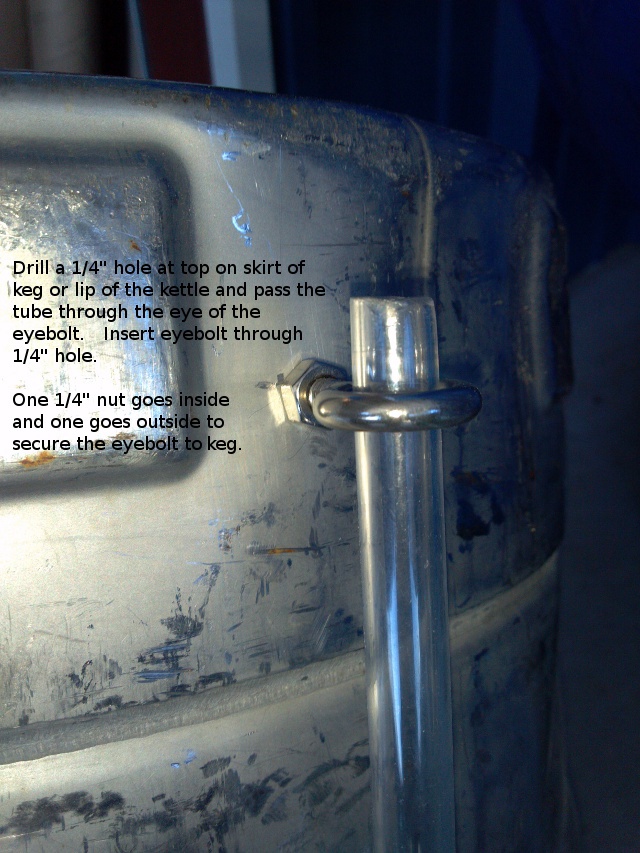

Locate the eyehook at the top, drill hole and use nuts to support the polycarbonate tubing. If in a kettle and you will fill above the nut you will need some teflon tape / small o-rings to seal the hole or it will weep. For a slow drip, slightly tighten the fitting until drip stops. If drip gets worse check the o-ring for proper install and ensure it is not popping out the sides of washer or locknut.

Categories

Categories